On 6 February, the A52 Clifton Bridge was suddenly closed for emergency repairs, bringing Nottingham to a virtual standstill. What has gone wrong - and how can such a major problem come as such a surprise? Civil engineer Alex Romankiw explains.

It's very easy for infrastructure to be taken for granted. Railways have been around for hundreds of years, roads for over two thousand years in one form or another. Often the travelling public do not realise how much work is required to keep infrastructure working - or how immense the disruption is when things go wrong.

On 6 February 2020, the residents of Nottingham found out exactly how bad things could get when a defect was detected in the A52 Clifton Bridge in south-west Nottingham. A major structural issue meant it was unexpectedly closed under emergency conditions, cutting a vital regional link and paralysing the city. Highways England have since announced that it'll be undergoing repair work, and unable to reopen fully, until 2021.

Understandably, there was outrage on social media, frustration at the disruption - and initially, information from Highways England was slow to appear. I decided to write a Twitter thread to explain why these sorts of incidents happen, and in this guest blog post I'll expand on that to show why we can expect more incidents like this.

Welcome to Nottingham

Nottingham is the largest city in the East Midlands, with excellent transport connections. The initial city grew on the Rivers Leen and Trent, and is now served by the M1 to the west, Midland Mainline rail connections, and East Midlands airport. The City Council is a majority stakeholder in the main bus operator, and also manages the modern tram network that was resurrected in 2001.

In the last decade a number of major projects have taken place to improve transport: Highways England dualled the remainder of the A46 between Leicester and Newark and the A453 between Nottingham and the M1. The tram network was expanded in 2015 with two additional lines, and the UK's first workplace parking levy commenced in 2012. In short, the city is very well-connected with plenty of transport options, and a growing movement within the city to discourage car use.

The A52 also serves Nottingham, running mostly as a dual carriageway east-west between Derby and Grantham. It forms the southern half of Nottingham's ring-road, following Clifton Boulevard, a 50mph three-lane dual carriageway with overhead gantry signage. It carries regional east-west traffic as well as local Nottingham traffic, a combination which rarely encourages smooth traffic flow.

As the road crosses the River Trent, it forms part of a seriously impressive junction complex, for a city ring road anyway! Two bridges carry the A52 across the Trent, multiplexing with the A453. On the north bank, a three level junction serves city-bound traffic on the A453. To the south another junction includes free-flow movements to the outbound A453 and local connections.

Meet the bridges

The junction formed in several stages. The western (northbound) bridge was built in 1958. The eastern bridge opened in 1972, and was wider, with four lanes southbound and one lane northbound. This means that, when heading north on the A52, the two lanes split: lane 2 heads north over the east bridge, and lane 1 joins the weaving three-lane section of the northbound bridge with the A453.

If you're struggling to follow that, the summary is: this bridge carries an awful lot of traffic!

The western bridge is made of post-tensioned concrete and, due to its age, was strengthened in the late 1990s when it was discovered that a quarter of its tendons were corroded. Tendons are long steel cables fixed under tension to pull the bridge together.

The eastern bridge is made from in-situ reinforced concrete forming pre-tensioned box beams. This is basically steel reinforcement bars (like the ones in the picture below) cast into concrete. This type of construction has two components:

Steel reinforcing bar (or "rebar" for short)

Rebar is made from carbon steel. Steel is very good at dealing with tensile forces such as bending and sliding forces (known as bending movement and shear force).

Concrete

Concrete is very good at dealing with compressive downwards forces.

Put the two ingredients together and you get a very strong material.

Reinforcing concrete is like baking. You build a large mould (usually out of timber or metal), fix the steel in place, pour the concrete, wait for it to set, and remove the moulds when it's done. This means we can use concrete to form bespoke shapes for the type of bridge or structure we want.

A question of rust

The steel used is usually carbon steel, which is susceptible to corrosion – notice how the bars are a brown-orangey colour like rust. To prevent corrosion, we could use stainless steel, but this is extremely costly and is sometimes weaker.

Corrosion takes two forms:

- Carbonation, a reaction between cement and carbon dioxide in the air, or

- Chloride penetration, a reaction caused by chloride ions, mainly found in de-icing salts deposited on the road by gritting and winter maintenance.

The reinforcing bars are usually protected from corrosion by being encased in concrete, but physical damage (like vehicle strikes, weathering, freeze-thaw action by water) can break away the concrete and expose the steel.

When the steel is exposed, the salts deposited by gritters can get to the bars and cause corrosion.

Corrosion also leads to rust as the air reacts with the steel, forming an oxide layer. The resulting expansion can blow the concrete out, exposing the steel: this is called spalling. Once exposed the corrosion can speed up and "chase along" the bar behind the concrete.

As the bar corrodes, its cross-sectional area is reduced. Since the bars deal with tensile loads in reinforced concrete, corroded bars have an impact on the ultimate load the structure is able to carry - so you can see why, when corrosion is detected, it can be a major issue.

You're probably thinking this sounds serious. It is! So how do we detect corrosion?

An inspector calls

The best way to detect corrosion is with a regular inspection schedule. There are two main types of inspection:

General

Carried out every 12-24 months, this is a quick check to make sure nothing has changed.

Principal

A detailed, close-up, touching-distance, thorough examination of the structure.

A principal inspection is generally every five years, although this can vary depending on the age, type and location of the structure. Other types of inspection can also be done. There is, of course, a wealth of guidance on bridge inspections as part of the Design Manual for Roads and Bridges [PDF], which sets out standards for building and maintaining highways.

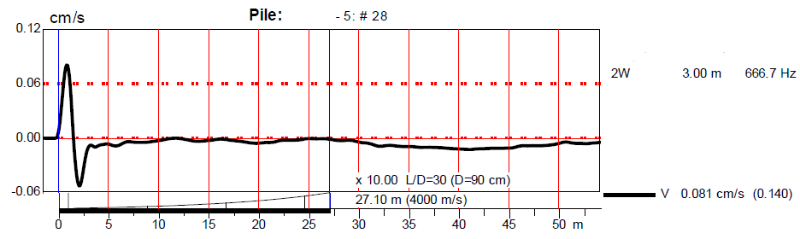

Earlier, we mentioned that corrosion can continue behind the concrete, which makes it difficult to detect. One way we can "look" through the concrete is using sonic logging. This sends an ultrasound signal through the concrete. Voids caused by corrosion will create a "blip" in the signal.

But sonic logging provides interpretive data, and hard-to-access areas can be missed. It's not usually part of an inspection unless there is already evidence of corrosion or other structural defects. The best way to examine corrosion is to break the concrete out and have a look.

Rubble trouble

Concrete corrosion is a well-known issue - a lot of research is going into it and there are all sorts of clever ways to solve it. One method is called cathodic protection, which is where an electrical current is passed through the structure to repel the chloride ions.

Maintenance projects on the M6 Bromford Viaduct and Spaghetti Junction, and the very long-running M5 Oldbury Viaduct works, have all been recent attempts to repair corrosion in bridge decks and piers.

To investigate and repair, the concrete must be broken out to expose the rebar. This involves mechanical breakers - jackhammers - or hydrodemolition, where the concrete is blasted out with high-pressure water jets. Both are noisy and dusty, and neither is a quick option.

If it's a small area, you can break out the concrete, chop the corroded bars, splice and couple new bars in, re-cast the concrete (or grout) and - hey presto! – it's fixed.

The picture below shows an example of a repair in progress. The concrete has already been broken out and the damaged bars have been cut. Couplers (with bolts on) now connect the bars back together. This work would take at least a week and relies on no further defects or corrosion being found. If the problem is worse than anticipated, we could be in for disruption for a long time.

So what exactly has happened at Clifton Bridge?

A nasty surprise

According to Highways England's contractors, a crack in the concrete was detected during a maintenance inspection in 2018. This triggered an investigation and then a maintenance scheme, which was being undertaken mainly from below the bridge decks by Balfour Beatty. Cabins and scaffolding were already in place below the bridge for this work.

The contractors were hydrojetting within the concrete box beams when they uncovered some loose lumps of concrete and then - more worryingly - a void. Upon closer inspection, some of the reinforcing tendons were exposed and corroded.

At approximately lunchtime on Thursday 6 February, Highways England were made aware of the situation and the potential risk that the structure was compromised. To protect the public, in case the bridge was actually unsafe, it had to be closed.

At 2pm, Highways England tweeted that the A52 would be closed later in the afternoon, perhaps at 4.30pm. In fact, the road was closed at 5.30, right in the middle of rush hour, and although long delays were reported that evening, it was only an indication of what was to come.

The road remained closed overnight, and then the Friday morning rush hour hit. Travel times of two hours to travel half a mile were reported. The tram and bus networks were crippled as junctions became blocked and vehicles broke down. At 9.30am, with the rush hour ending, there were two-mile queues on the approaches to the closure.

On Friday afternoon, a statement was issued, confirming that water damage had corroded steelwork within the bridge, and that HE planned to partially reopen the bridge the following week.

Other emergency measures were put into place:

- All non-critical roadworks in the Nottingham area were suspended.

- Highways England stepped up Traffic Officer patrols not just on the A52 but across the surrounding network.

- Free breakdown recovery was provided.

Over the weekend, the traffic chaos continued, and with entertainment and sporting events in the city being held, other river crossings such as Trent Bridge quickly ground to a halt under the pressure. Police were deployed to key junctions to try to keep traffic moving.

No quick fix

While all this was going on, engineers were hard at work. Structural specialists were assessing the bridge and maintenance crews were working quickly to clear out the damaged area and make a repair.

On Monday 10 February, Highways England announced their intention to open a single traffic lane by Wednesday - hooray! On Tuesday, they announced they would try to open the single lane for the Tuesday evening rush-hour - double hooray! Unfortunately, their optimism was misplaced, and it wasn't until Wednesday that a lane was opened. Presumably there were more nasty surprises to deal with on the Tuesday afternoon.

The lane reopening provided only minor relief, since there are still four lanes closed to traffic. Normally the two Clifton Bridges provide a total of eight lanes across the river, but only four are presently available. Only one lane could be reopened if the repair work was going to continue.

The restriction is making for some interesting arrangements. The lane doesn't follow the existing ones across the road surface; it's been set out specially, protected with a temporary barrier, and is temporarily marked with white lines.

Eternal vigilance

Unfortunately, many of the concrete and steel structures in the UK are getting to an age where they require more and more maintenance and upkeep to remain in service. Some structures, like the M6 viaducts near Birmingham or the M4 Brentford Viaduct in West London, now need constant maintenance works.

This problem isn't unique to roads. Rail structures like the Severn Tunnel and Forth Bridge require similar round-the-clock interventions to keep them open for the travelling public.

Equally, emergency closures like the one the Clifton Bridge is suffering have also happened in the past. The closure of the A4 Hammersmith Flyover in 2011 was well reported, as were the problems affecting the A90 Forth Road Bridge in 2017.

The good news is that the UK is experienced in maintaining a large portfolio of highways structures. Compared with the rest of the world, our inspection regimes are particularly stringent and we have an excellent pool of engineers keeping the network running. The problem isn't inattention; it's that even close attention is sometimes not enough to spot an issue before it becomes serious.

So if you're stuck in the Nottingham traffic, or indeed a future emergency closure, I hope this gives you some idea of how and why these things happen.

Comments

Two things come to mind.

- Isn't it time to stop the use of road salt on the carriageways of bridges like this ? AIrports never use salt to clear runways, they use urea instead. Yes it is much more expensive, but surely it would be worth it for the small percentage of carriagway mileage involved. People probably wonder why salt mustn't get near aircraft, they are aluminium and don't rust right ? Well yes, they don't rust but can suffer from crevice corrosion where atmospheric oxygen is deficient, but water is present, especially salty water. Aircraft on aircraft carriers have to be specially protected, and this makes carrier aircraft rather more expensive than land-based warplanes.

- Has any study been made into service life if the steel reinforcer bars were galvanised ? Galvanising is basically the sacrificial anode principle, the zinc being sacrificed instead of the steel. In fact, going much further, zinc anodes, (large lumps of zinc) are used on ships hulls and provide protection even many feet away from the zinc anode. Similar should work with reinforcing although the chemistry of concrete would need to be factored into the protection equation. On ships, the zinc anodes eventually disappear as they are designed to do, and are replaced when the ship is docked for hull maintenance.

Urea was done away with many years ago, the stuff now used is called clearway. Urea was obviously getting in to water supply so its use was stopped. That meant however that airfields had large stocks of the stuff and no one knew what to do with it. In the days of the cold war grit could be used on runways as a last resort.

Never thought that i'd enjoy reading such a technical article on bridges so just to say that it was very informative and actually a good read!

I think it does highlight the issue over long-term costs of such projects in terms of maintenance and the knock-on costs for commuters. It would seen sensible that such projects should be costed differently to make allowances for more initial capital expense with greater longevity / lower upkeep in mind.

As a layman, I have no understanding of the required design criteria but am also wondering why things such as FRP – fibre reinforced polymer is not being used more widely to repair and build bridges. I understand it is strong, resists fatigue and corrosion and has already been used on a road bridge replacement near Bristol.

I also think there's a very good point that, unlike the Genoa Bridge disaster, there seems to be a much more robust inspection regime in the UK and despite the huge delays caused by remedial work, it's still a small price to pay for safety.

An excellent article, Alex Romankiw: you have explained the issue really well, striking a good balance between providing enough technical detail and keeping the article comprehensible to anyone with an interest in how infrastructure is monitored, maintained and repaired. You have a rare skill!

The A52 is certainly not mostly a dual carriageway east-west between Derby and Grantham. It is dualled west of Nottingham but from Nottingham to Grantham it is a ghastly single-carriageway road just as 50 years ago when I lived there.

I live in Nottingham, and it snowed that Thursday as well! I think Nottingham was declared the most congested city that Friday too. Made life extremely difficult!

Thank you for writing this brilliant article!

Add new comment

Picture credits

- Photographs of Clifton Bridge from below, rebar, spalling concrete, ultrasound graph, and repairs to rebar are by Alex Romankiw and used with permission.

- Aerial photograph showing bridge closure © 2020 Google.

- Photograph of work at Spaghetti Junction taken from an original by Elliott Brown and used under this Creative Commons licence.

- Photographs of scaffolding underneath the Clifton Bridge taken from originals by @kevjs1982 and used with permission.

- Photographs of exposed rebar inside Clifton Bridge, engineer inside bridge beam and engineers climbing to access hatch are taken from originals released by Highways England.

I agree that British engineers are doing a good job. Consider the tragedy in Genoa by comparison.